Unparalleled genius: High-performance plastic – PTFE – Seals

We are also proud to be able to be quick off the mark. Our team consists of skilled craftspeople who competently apply their expertise. These means we are able to provide bespoke production, even in small amounts, at attractive lead times.

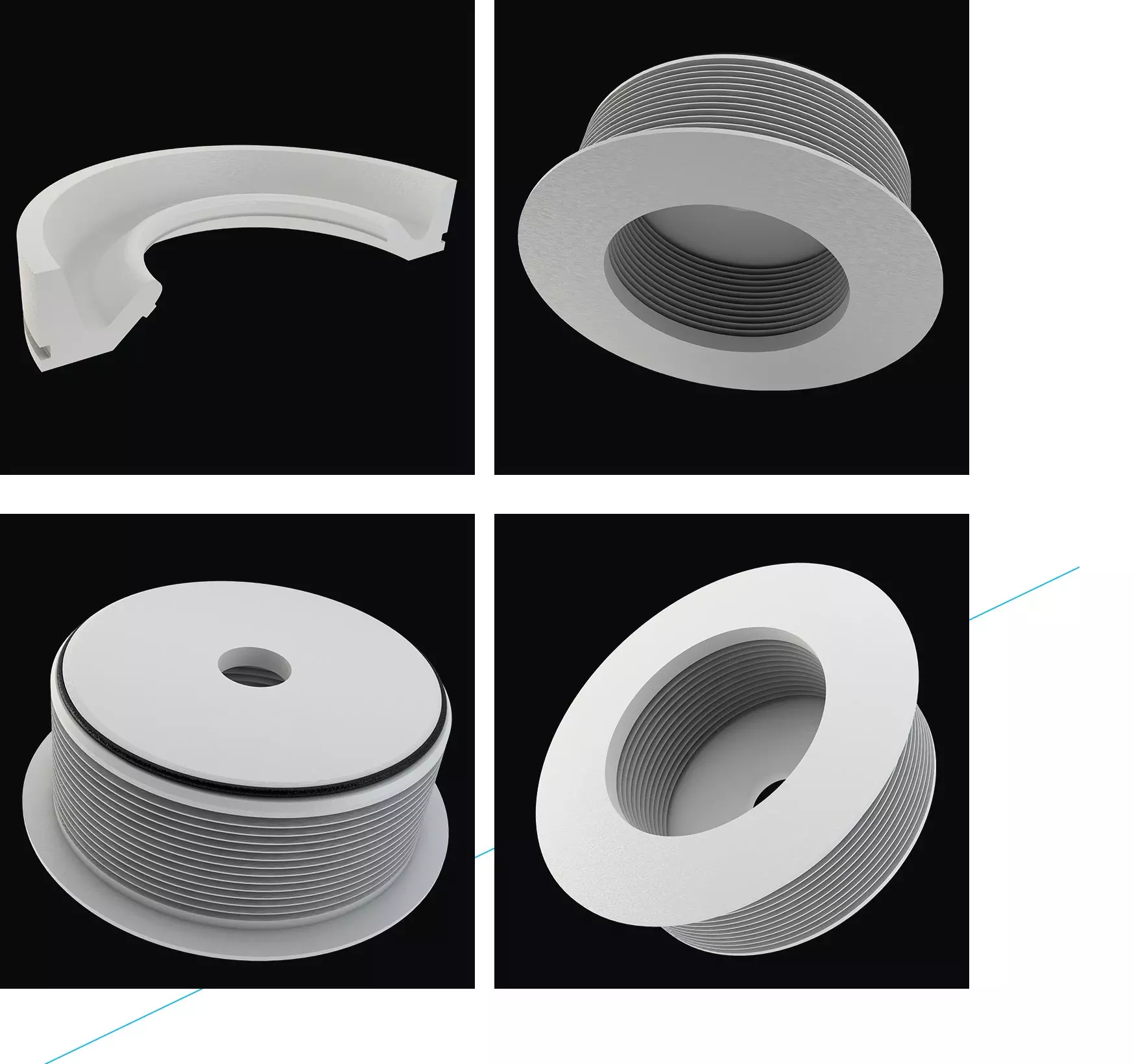

PTFE finished components

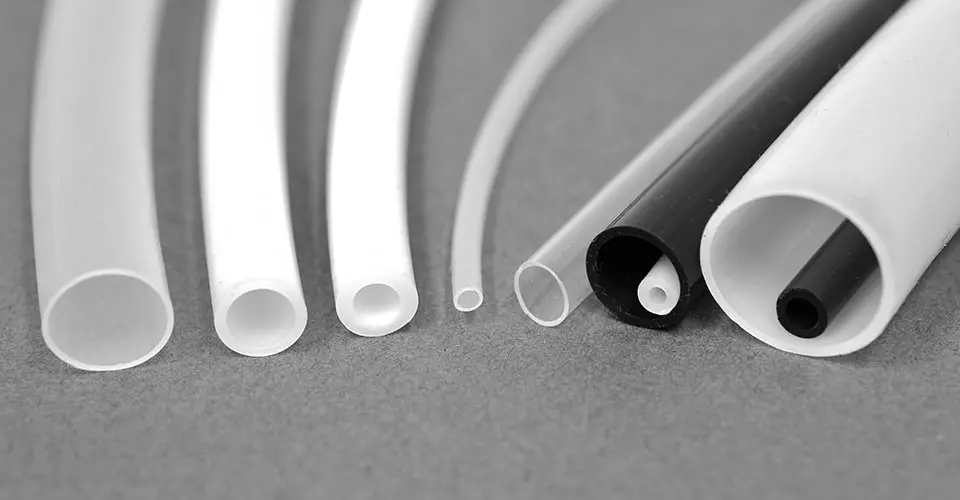

We produce finished standard components, primarily using PTFE, in all available variants: rings, coated O-rings, bushings, collars, balls, bellows, seals – as turned and milled parts. We specialise in bespoke products – wholly in keeping with your requirements, your specification or your drawings.PTFE semi-finished products

Standardised, as per customary European and American standards and of course, adhering to strict quality guidelines, we offer our customers and distributors semi-finished products in PTFE (+compounds), ePTFE and other high-performance plastics, in a variety of types, ranging from tubing, panels, rods to sheeting.Technical requirements

For technical requirements we offer: stuffing box gland packing and respective packing cutters, pure graphite rings, tubing and threaded tapes. Speciality: PTFE-coated glass fabric sheeting and tapes in self-adhesive and adhesive variants – endless or assembled in the preferred format.3D Printing

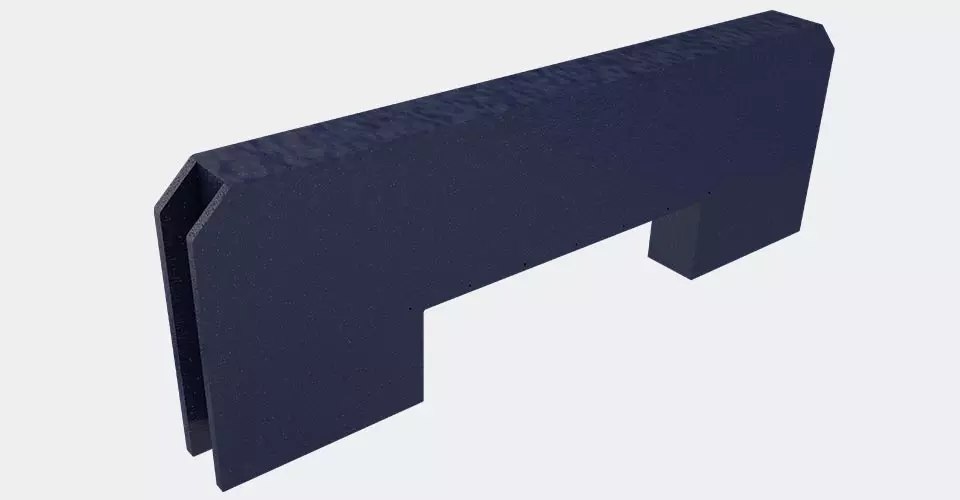

We offer production using 3D printing for prototypes or master samples, as a cost-effective alternative to conventional production methods. We print your preferred component in various plastics (ABS, TPU, PLA, PEEK, polyamide, CPE, polycarbonate), which – ideally – you will have sent to us in advance as a STEP file.From prototypes to finished components

Bespoke and made-to-measure; in small and large amounts – this provides a general description of our product range. However what really sets us apart is our passion for high-quality processing using high-performance plastics. Depending on requirements, we produce small and large batches, individual parts, replacement parts, samples and prototypes. Punched, turned and milled parts, and also cuttings from PTFE, modified PTFE, PTFE+ compounds, ePTFE, PA, PEEK, PP, PVC and POM are processed. On customer request we are also happy to process any other high-performance plastic.Find out more

High-quality PTFE - Norm ISO 9001

Our clear-cut quality awareness was officially confirmed in May 2017. Since that time we have been an ISO 9001 certified company. We regard this certification as significant affirmation of our commitment and our endeavours to provide the highest performance. After all, as a small business, with around 12 employees, this award is an outstanding achievement. That said, we regard it as our duty to continue to develop further. We bring a great deal of experience but are indeed very well aware that we are able to learn from, and improve with, each and every component.Find out more

Master samples via 3D printing

Innovations, new ideas, approaches and designs – anyone who wants to move forward, has to try things out, work meticulously and think outside the box. We are a small business, with a streamlined organisational structure. Our team consists of passionate tradespeople who are more than happy to take on challenges. It is highly likely that this is the reason we are appreciated globally as a partner for new developments. That we incorporate our expertise is a matter of course for us. We on a level playing field with all involved, because we have one common goal – your success.

Thanks to our many decades of experience, we are well-positioned to assess materials, requirements and applications and make the desired components, using various methods, as per your job specifications. As required, we produce intricate, individual elements using 3D printing. It is predominantly high-performance plastics that are used, including PEEK, polyamide, polycarbonate, ABS, PLA and TPU. Using these variants saves on production costs. Another bonus is that we are able to produce within reasonable time-frames.

Send request

Possible applications

Plastics expert for seals, rings, bushings, piping and rods

What started out as a motivated one-man business, today is an impressive business for a specific market which has special requirements. Franz Seiwald realised that there were needs on the customer-side that had not, or had been merely little fulfilled, until that time. More than 30 years have passed since then – the philosophy and basic approach remain identical:

'to develop and implement products made from high-performance plastics together with our customers, that meet the highest and most complex requirements.'

Technophyon specialises in the production of PTFE finished components and contemporary sealing products – in small and large production runs. High quality turned and milled components are made according to the customer's drawing, design and expectations.

To the fore with every assignment is a 'cooperative partnership', since it is only by working together than the best results are obtained. The family-based structure has proven time and again to be key to the success for the meeting the highest requirements, with the best quality.

Customer satisfaction

We regard our customers as royalty – with their crowns being made from high-performance plastic, of course. After all, we place a great deal of emphasis on ensuring friendly, reliable and professional cooperation. The best solutions arise from close, direct interaction. In so doing, we are able to work efficiently and deliver the result you want.Quality

To be able to work in the high-quality manner, as we expect of ourselves, requires considerable 'all-round thinking' from everyone involved. We think collaboratively and progressively, consider carefully and implement our expertise in such a way that all our customer's needs are met. Autonomous actions are deeply anchored within our DNA.Partnership

Trustful, respectful cooperation – on all levels – that is what epitomises Technophyon. This concerns our suppliers in particular, the majority of whom we have nurtured a business relationship with, spanning many years. We can depend on one another and learn from one another in ongoing exchange, while also implementing enhancements.Hochfilzen – in the heart of Europe

Our company, Technophyon, is located almost exactly in the centre of Europe, so we often see ourselves as a link between north and south, east and west. With our geographical location, we Austrians have, over the course of time, learned to nurture a special balance, which extends to everyone. In any event, we appreciate a great deal our customers and partners bespoke requirements.

Hochfilzen, the town in which our company is located, has more than 1100 inhabitants and is located at around 1000 metres altitude in the district of Kitzbühel, in the state of Tyrol, Austria. In the past few years lots of innovative companies have been set up here who implement their ideas on a global basis. Due to its high magnesite deposits, this region is highly significant. And as an international location, Hochfilzen has a key role to play in Biathlon events. The World Championships have already taken place here on several occasions.